Categories

Send Message

Chemical Bag Storage Racks

Chemical Bag Storage Racks: Ensuring Safety and Efficiency

The right storage solutions can prevent accidents, improve organization, and enhance productivity. Chemical bag storage racks offer a robust and reliable method to store and manage chemical bags in various industrial settings.

Importance of Proper Chemical Bag Storage

Chemical bags contain substances that can be hazardous if not handled and stored correctly.

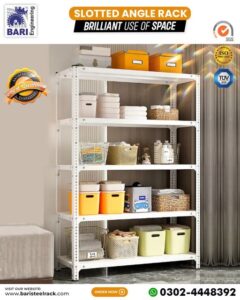

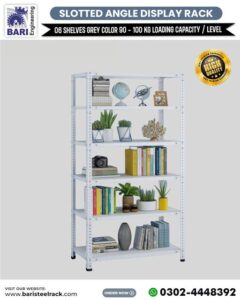

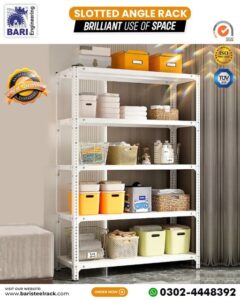

Customizable Design

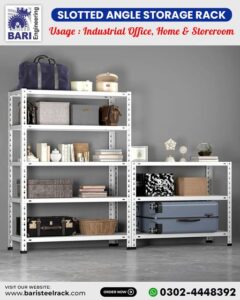

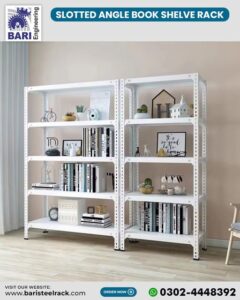

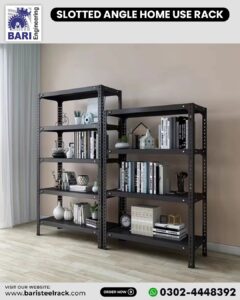

These storage racks can be customized to fit the specific needs of your facility, including the use of custom plastic chemical bags.

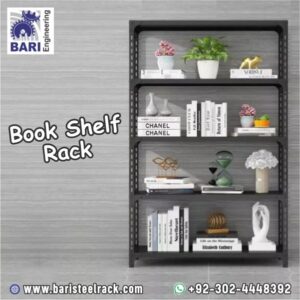

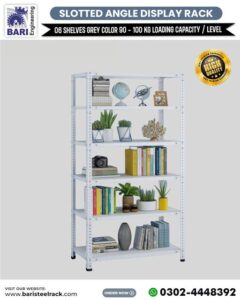

Easy Access and Organization

The design of a chemical bag storage rack allows for easy access to stored materials. This is crucial for maintaining efficiency in busy industrial environments.

Features of Chemical Bag Storage Racks

Benefits of Using Chemical Bag Storage Racks

Enhanced Safety

By using specialized storage racks, you reduce the risk of accidents.

Improved Efficiency

With a well-organized storage system, employees can quickly locate and retrieve the materials they need.

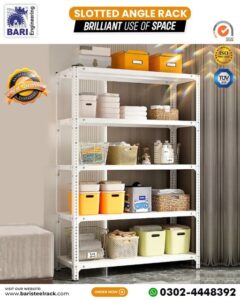

Space Optimization

Storage racks for bags are designed to maximize the use of available space. They allow for vertical storage, freeing up valuable floor space for other activities.

Choosing the Right Chemical Bag Storage Racks

Quality and ComplianceEnsure that the chemical storage racks you choose comply with relevant safety standards and regulations.

Professional Installation

For optimal safety and performance, it is recommended to have the bag racks professionally installed. Expert installation ensures that the racks are securely anchored and properly aligned.

Maintenance and Inspection

Regular maintenance and inspection of chemical bag storage racks in Pakistan are essential for ensuring their continued effectiveness. Check for any signs of wear and tear, and address issues promptly to maintain safety standards.

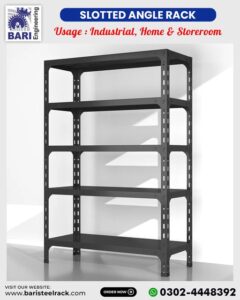

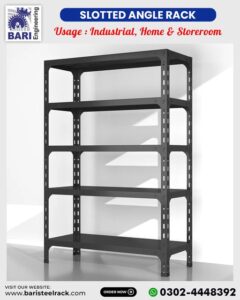

Durability and Stability

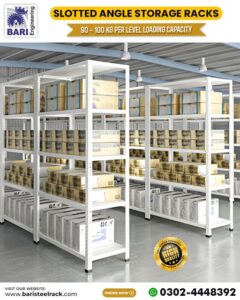

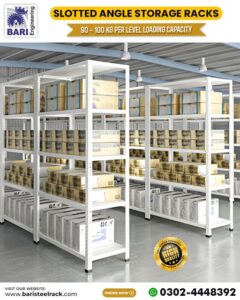

Chemical bag storage racks for sale are built to withstand heavy loads and harsh conditions. It is a storage system designed to stack materials in horizontal rows with multiple levels. With proper chemical bag storage racks, warehouse managers maximize space and optimize Warehouse Racking organization for efficiency and a streamlined picking process. Warehouse layout plays a major role in the Warehouse Racking/shelving System, as aisle width, docking locations, shipping areas, and other warehouse components affect warehouse racking/shelving options. Pallet racking is the most common form of chemical storage rack.

Components of Chemical Storage Racks

The upright frames are columns that stand upright and go as high as possible to increase the capacity of the warehouse.

Chemical Storage Racks Advantages

The warehouse racking system is reliable. It allows you to store your material for a long period.

Adding a racking system can double and sometimes even triple the amount of materials you’re able to handle in your warehouse.

Direct access to each pallet

- Simple stock management

- Adaptable to any product volume, weight, or size

Categories

Send Message

Chemical Bag Storage Racks

Chemical Bag Storage Racks: Ensuring Safety and Efficiency

The right storage solutions can prevent accidents, improve organization, and enhance productivity. Chemical bag storage racks offer a robust and reliable method to store and manage chemical bags in various industrial settings.

Importance of Proper Chemical Bag Storage

Chemical bags contain substances that can be hazardous if not handled and stored correctly.

Customizable Design

These storage racks can be customized to fit the specific needs of your facility, including the use of custom plastic chemical bags.

Easy Access and Organization

The design of a chemical bag storage rack allows for easy access to stored materials. This is crucial for maintaining efficiency in busy industrial environments.

Features of Chemical Bag Storage Racks

Benefits of Using Chemical Bag Storage Racks

Enhanced Safety

By using specialized storage racks, you reduce the risk of accidents.

Improved Efficiency

With a well-organized storage system, employees can quickly locate and retrieve the materials they need.

Space Optimization

Storage racks for bags are designed to maximize the use of available space. They allow for vertical storage, freeing up valuable floor space for other activities.

Choosing the Right Chemical Bag Storage Racks

Quality and ComplianceEnsure that the chemical storage racks you choose comply with relevant safety standards and regulations.

Professional Installation

For optimal safety and performance, it is recommended to have the bag racks professionally installed. Expert installation ensures that the racks are securely anchored and properly aligned.

Maintenance and Inspection

Regular maintenance and inspection of chemical bag storage racks in Pakistan are essential for ensuring their continued effectiveness. Check for any signs of wear and tear, and address issues promptly to maintain safety standards.

Durability and Stability

Chemical bag storage racks for sale are built to withstand heavy loads and harsh conditions. It is a storage system designed to stack materials in horizontal rows with multiple levels. With proper chemical bag storage racks, warehouse managers maximize space and optimize Warehouse Racking organization for efficiency and a streamlined picking process. Warehouse layout plays a major role in the Warehouse Racking/shelving System, as aisle width, docking locations, shipping areas, and other warehouse components affect warehouse racking/shelving options. Pallet racking is the most common form of chemical storage rack.

Components of Chemical Storage Racks

The upright frames are columns that stand upright and go as high as possible to increase the capacity of the warehouse.

Chemical Storage Racks Advantages

The warehouse racking system is reliable. It allows you to store your material for a long period.

Adding a racking system can double and sometimes even triple the amount of materials you’re able to handle in your warehouse.

Direct access to each pallet

- Simple stock management

- Adaptable to any product volume, weight, or size