Categories

Send Message

Slotted Angle Racks

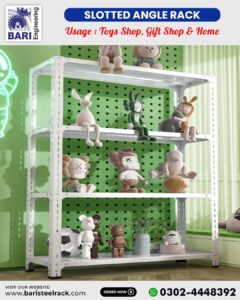

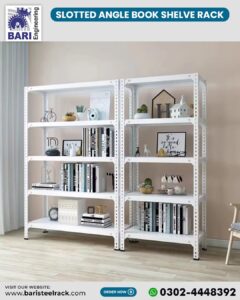

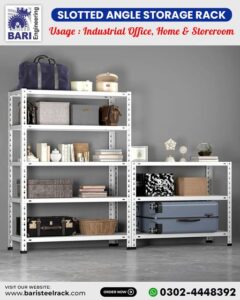

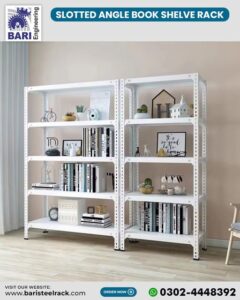

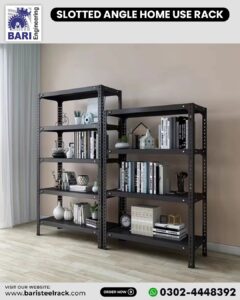

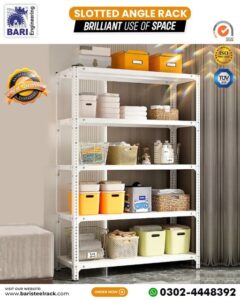

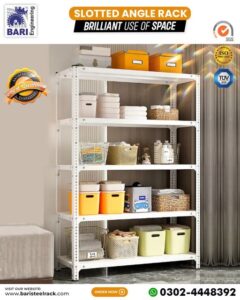

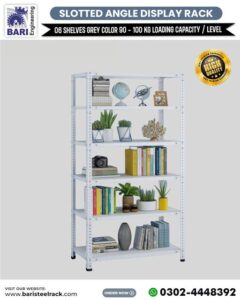

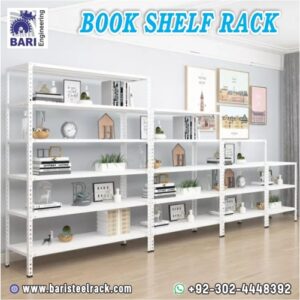

We offer a wide range of slotted angle rack that provide numerous benefits for efficient storage solutions. As a trusted Slotted angle racks manufacturer, we ensure our racks are designed with precise compartments, lightweight yet durable materials, and water-resistant properties.

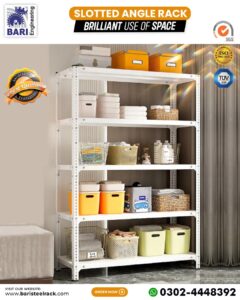

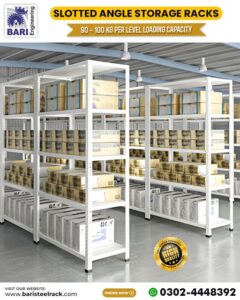

Our slotted angle racks heavy duty have superior load-bearing strength, corrosion protection, and dent resistance. These racks are easily movable, with adjustable height and wide storage space.

Whether you’re looking for slotted angle rack price details or need bulk orders at competitive rates, we provide solutions tailored to your needs.

They are easy to install, maintenance-free, and feature equally spaced Slotted Angle Shelves with no sharp edges.

We also offer slotted angle racks price in Pakistan for businesses looking for cost-effective storage options. Customized sizes are available in slotted angle racks pakistan to meet specific requirements. Our racks are highly durable and provide a stable base on any surface.

Explore the advantages of our adjustable Slotted Angle Storage Racks And Shelves, including cost-effectiveness, ease of assembly, and the ability to create various structures.

You can also find our Slotted Angle Rack Online, making it easy to purchase high-quality storage solutions from anywhere.

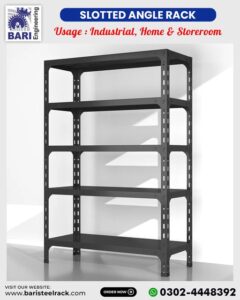

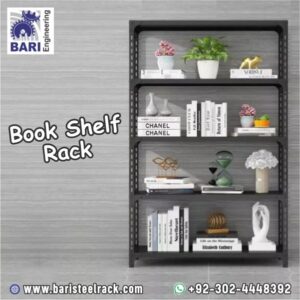

We offer different types of racks,Like a Slotted Angle Rack, including industrial, Rolex, stainless steel, and steel options.

Whether you need Slotted angle racks in bulk price or are interested in the slotted angle price per kg, we provide transparent pricing.

Choose our reliable and versatile Slotted Angle Shelvings for your storage needs.

Slotted Angle Racks

We offer a wide range of slotted angle rack that provide numerous benefits for efficient storage solutions. As a trusted Slotted angle racks manufacturer, we ensure our racks are designed with precise compartments, lightweight yet durable materials, and water-resistant properties.

Our slotted angle racks heavy duty have superior load-bearing strength, corrosion protection, and dent resistance. These racks are easily movable, with adjustable height and wide storage space.

Whether you’re looking for slotted angle rack price details or need bulk orders at competitive rates, we provide solutions tailored to your needs.

They are easy to install, maintenance-free, and feature equally spaced Slotted Angle Shelves with no sharp edges.

We also offer slotted angle racks price in Pakistan for businesses looking for cost-effective storage options. Customized sizes are available in slotted angle racks pakistan to meet specific requirements. Our racks are highly durable and provide a stable base on any surface.

Explore the advantages of our adjustable Slotted Angle Storage Racks And Shelves, including cost-effectiveness, ease of assembly, and the ability to create various structures.

You can also find our Slotted Angle Rack Online, making it easy to purchase high-quality storage solutions from anywhere.

We offer different types of racks,Like a Slotted Angle Rack, including industrial, Rolex, stainless steel, and steel options.

Whether you need Slotted angle racks in bulk price or are interested in the slotted angle price per kg, we provide transparent pricing.

Choose our reliable and versatile Slotted Angle Shelvings for your storage needs.