Categories

Send Message

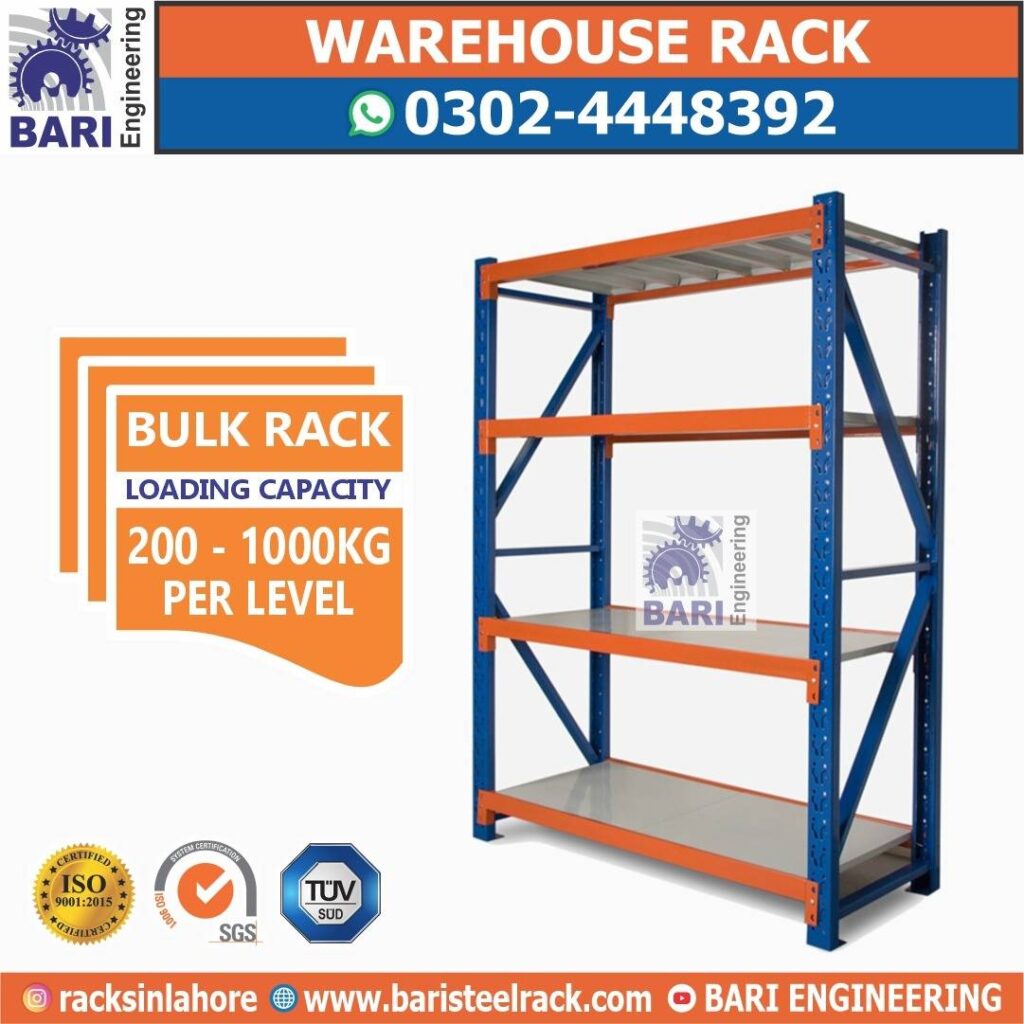

Warehouse Rack

Warehouse Rack is also referred to as Warehouse Rack. It is a storage system designed to stack materials in horizontal rows with multiple levels. With proper warehouse racking, warehouse managers maximize space and optimize warehouse racking system organization for proficiency and a streamlined picking process.

Warehouse Rack layout plays a major role in the best warehouse racking systems, as aisle width, docking locations, shipping areas, and other warehouse components affect warehouse racking solutions. Pallet racking is the most common form of shelving and racks warehouse systems.

Components of Warehouse Racking/shelving system

Load beams, also called step beams, are support structures that allow for materials to be stored in a horizontal form. The load beams are fit onto the upright framework that enables the rack storage warehouse system.

Upright frames are a warehouse racking manufacturers framework designed to fit into the warehouse’s design. They are columns that stand upright and rise as high as possible to increase the warehouse’s capacity. Holes are then drilled into these upright columns at regular intervals to mount the load beams.

Diagonal braces are welded or bolted between two upright columns to increase rigidity and strength. They are also referred to as horizontal braces or upright frame lacing.

Wire decking is used to increase safety while storing materials in warehouse racking. The wire decking is usually a wire mesh that is fit to the horizontal columns to prevent stored materials from falling from the rack structure. The mesh is used as opposed to a solid base so that dirt does not accumulate on the shelves. The mesh is also used to ease the identification of the specific materials stored in each shelve. This is because, with the mesh, you can see through even to highly placed shelves and know which materials are stored at any location.

Foot plates, also known as face plates, are usually placed at the base of the columns to increase their stability. These anchors are bolted in to support the columns to the concrete floor firmly.

Warehouse Racking/ Shelving System Advantages

One big advantage of racking in pharma warehouses is that it helps save space. The layout in which the racks are built allows for the utilization of wasted vertical space.

The warehouse racking system is reliable. It allows you to store your material for a long period.

It’s much cheaper to employ a racking system than double the square footage of an existing warehouse.

Adding a racking system can double and sometimes even triple the number of materials you’re able to handle in your warehouse.

- Direct access to each pallet

- Simple stock management

- Adaptable to any product volume, weight, or size