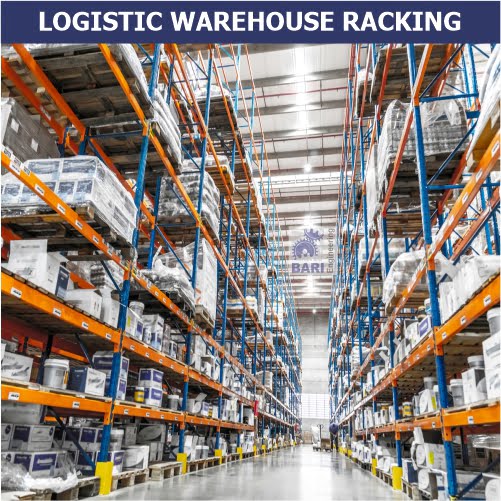

Logistic Warehouse Racking the stands where pallets can be stored. Each rack can effectively hold hundreds of pallets, depending on the size. Logistic Warehouse Racking is excellent for managing space within the warehouse or a store. It can be defined as multi-level structured units used to hold stacks of heavy Pallet Shelves, which are a popular means of storage for literally any industry. A lot of warehouses store their products on Pallet Rack Beams. Whether it be fresh fruit or microwave ovens on these trays, every supplier needs an efficient way to store them.

Features of Selective Pallet Racks

- Save Space

- Provide Safety

- Durability

- Accessibility

- Connivance

Advantages of Selective Pallet Racks

- First:

- Second:

- Third:

The high-quality steel and joining materials in Pallet Racks guarantee long-term use. These racks are designed specifically to endure the rigors of daily operations, ensuring lasting durability. pallets going in and being taken out and to hold the weight of Pallet Rack Beams being stored.

- Fourth:

Pallet Racks are easily accessible by forklifts from both ends and on either side, aiding production in a manufacturing plant. Easy maneuverability around the racks is crucial for forklifts to obtain needed items precisely when required.

Types of Selective Pallet Racks

Drive-in and drive-through

Drive-in and drive-through (sometimes spelled drive-thru) configurations enable forklifts to directly access stacked bay rows. The distinction between them lies in entry points: drive-in racks have a single entry/exit, while drive-thru systems offer access at both ends. Drive-in systems employ a “last in, first out” (LIFO) storage method due to their single entrance.

Push-back Pallet Racks

Push-back pallet rack systems organize space by depth rather than width, significantly reducing aisle space and boosting storage density. In this setup, each bay can accommodate up to six pallets deep. Logistic pallet racking stores pallets on wheeled carts fitting onto rails angled slightly toward the load/unload side, harnessing gravity to save substantial energy when moving heavy loads.

Selective Pallet Racks, a widely used pallet racking system, typically come in two configurations: roll-formed (clip-in) and structural bolt-together configurations.

Selective Pallet Racks, a widely used pallet racking system, typically come in two configurations: roll-formed (clip-in) and structural bolt-together configurations.

- Manufacturers commonly produce roll-formed selective racks in a ‘teardrop’ style. Mounting clips hold the horizontal load beams where pallets rest. The adjustable clips in teardrop configurations allow easy modification of shelf heights to accommodate different load sizes. This convenience suits warehouses needing to store various product sizes.

- Structural Pallet Rack systems closely resemble roll-formed Pallet Shelves, but they attach horizontal load beams to uprights with bolts. These beams boast significantly higher weight-bearing capacity. The bolt fixings enable the construction, reconfiguration, dismantling, and reuse of these racks as needed.

Double Deep Rack

Double Deep Rack resembles a Selective Rack but stores items two rows deep instead of one, necessitating specialized pallet handling equipment. Employing a specialized forklift unit with a double deep handling attachment increases storage capacity compared to Selective Racking. It can enhance Pallet Rack Beam storage by up to 10-15%, contingent on the layout.