Static Pallet Racking

Static Pallet Racks serve as stands for storing pallets. Each rack can effectively hold hundreds of pallets, depending on size. Pallet rack systems excel in managing space within warehouses or stores. These systems comprise multi-level structured units that hold stacks of heavy Static Pallet Racking, a popular storage method across various industries. A lot of warehouses store their products on Pallet Rack Beams. Every supplier requires an efficient way to store fresh fruit or microwave ovens on these trays.

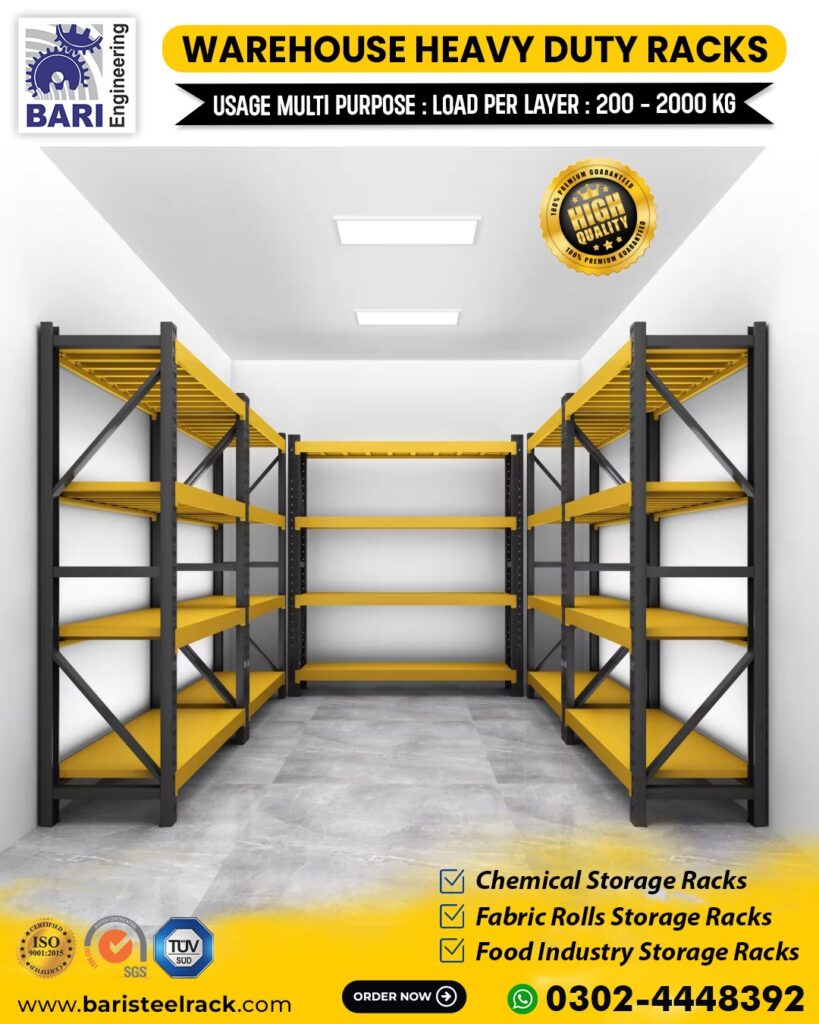

Features of Static Pallet Racks

- Save Space

- Provide Safety

- Durability

- Accessibility

- Connivance

Advantages of Pallet Racks

Static Pallet Racks offer a significant space-saving advantage. Their construction allows businesses to utilize vertical space rather than valuable floor space, providing opportunities to achieve goals efficiently. The setup of a Pallet Shelf Racking System enables forklifts to reach upward and retrieve Pallet Shelves as needed. The stacking ability of Pallet Rack Beams not only saves space but also reduces costs.

Static Pallet Racks offer safety as a key benefit. Manufacturers use high-quality materials to construct these racks and extensively test them for stability and weight-bearing capacity. You’ll receive comprehensive instructions on positioning and utilizing the racking system to enhance safety, reducing the likelihood of injuries and mishaps.

Static Pallet Racks use high-quality steel and joining materials, guaranteeing long-lasting durability. Their design specifically withstands the rigors of use for many years. Pallet rack beams go in and out, supporting the weight of stored pallets.

Pallet racks are easily accessible by forklifts from both ends and sides. Maintaining accessibility is crucial when production in a manufacturing plant is at risk. Fork trucks require ease of maneuverability around the racks to retrieve necessary items promptly.

: A Pallet Rack is a convenient system that operates efficiently when properly set up and utilized by warehouses or plants. These racks are designed to enhance storage capacity, expedite operations, and improve safety. While the significance of Pallet Shelves might be overlooked, implementing a functional system in any area consistently bolsters overall business performance.

Types of Static Pallet Racks

Drive-in and drive-through

Drive-in and drive-through (sometimes spelled Drive-thru) storage rack configurations enable forklifts to drive directly into stacked bay lanes. The distinction between drive-in and drive-thru pallet rack systems lies in whether the bays have entry points at one or both ends. Drive-in racks use a common entry/exit, employing a LIFO (last in, first out) storage method.

In a drive-in system with a single entrance, the last pallet placed is the first to be removed. Conversely, a drive-thru system, featuring two entry points, allows for a FIFO (first in, first out) storage method. Pallets are loaded at one end and pushed to the opposite side, ensuring the first pallet put in is the first taken out. This system is ideal for items with expiration dates or concerns regarding shelf life.