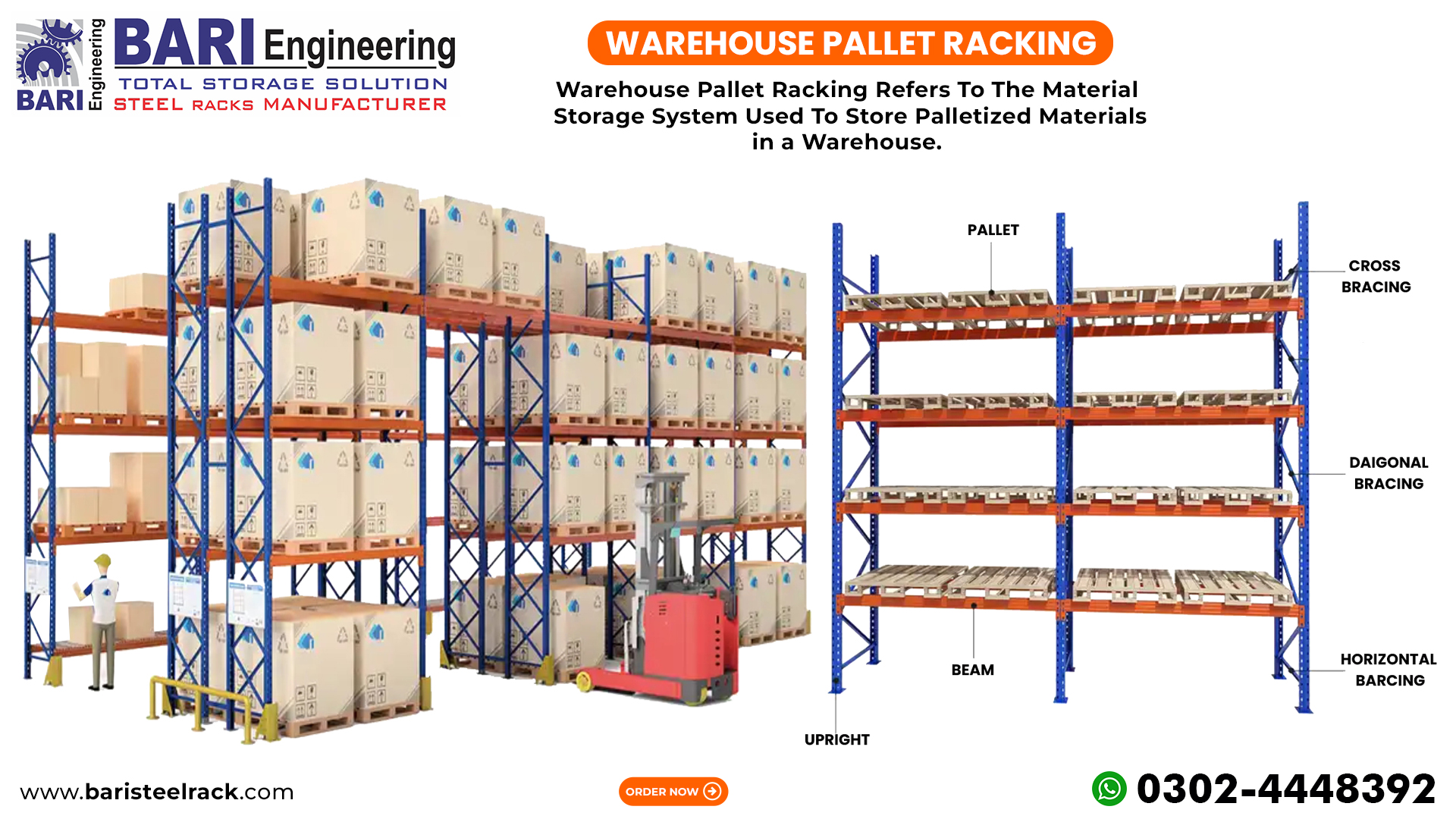

Logistic Warehouse Racking

Logistic Warehouse Racking the stands where pallets can be stored. Each rack can effectively hold hundreds of pallets, depending on the size. Logistic Warehouse Racking is excellent for managing space within the warehouse or a store. It can be defined as multi-level structured units used to hold stacks of heavy Pallet Shelves, which are a popular means of storage for literally any industry. A lot of warehouses store their products on Pallet Rack Beams. Whether it be fresh fruit or microwave ovens on these trays, every supplier needs an efficient way to store them.

Types of Logistic Warehouse Racking Systems

- Selective Pallet Racking: The most common type, ideal for warehouses needing easy access to each pallet.

- Benefits: Cost-effective, adaptable, and easy to install. Suitable for warehouses with a high SKU (Stock Keeping Unit) count.

- Drive-In/Drive-Through Racking

- A high-density storage system that allows forklifts to drive directly into the rack.

- Benefits: Maximizes storage space and is ideal for storing large volumes of similar products. Best for last-in, first-out (LIFO) or first-in, first-out (FIFO) inventory methods.

- Push-Back Racking

- A dynamic system where pallets are stored on a slight incline and move forward as items are removed.

- Benefits: Saves time by reducing aisle space and providing deep storage options with multiple SKU access.

- Cantilever Racking

- Designed for storing long or bulky items such as pipes, lumber, or furniture.

- Benefits: Flexible and adjustable, making it perfect for items that are difficult to store using traditional racks.

- Pallet Flow Racking

- A gravity-based system where pallets move along rollers from the loading to the picking end.

- Benefits: Enhances inventory turnover and is ideal for FIFO stock management.

- Selective Pallet Racking: The most common type, ideal for warehouses needing easy access to each pallet.