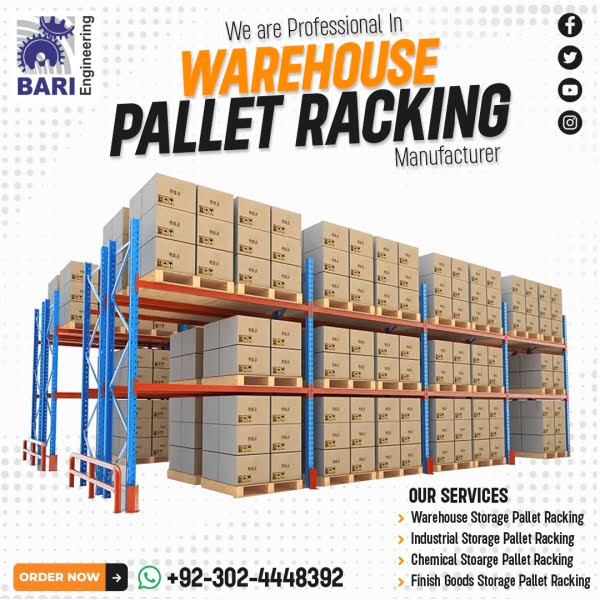

Selective Pallet Racks store pallets efficiently, accommodating hundreds based on size. These systems manage warehouse space well, comprising multi-level units for heavy Pallet Shelves. Industries widely use them for storage. Warehouses commonly place products on Pallet Rack Beams, ensuring efficient storage for various items, from fresh fruit to microwave ovens.