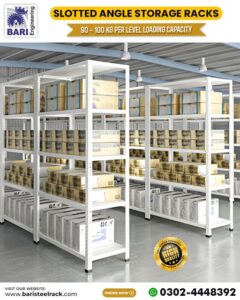

Raw Material Warehouse Pallet Racking

Introduction to Pallet Racking for Raw Material Storage

Efficient storage is key to streamlined operations in any warehouse, especially when it comes to raw materials. Pallet racking systems provide a structured solution, allowing businesses to store and access materials safely and effectively.

Benefits of Pallet Racking Systems

- Maximized Storage Space: Optimize vertical space, making the most of the warehouse’s capacity.

- Enhanced Organization: Clearly defined spaces for different materials improve inventory management.

- Improved Safety: Properly installed pallet racking systems reduce the risk of accidents and damage to materials.

- Scalability: Easily adjustable to accommodate future growth or changes in inventory.

Types of Pallet Racking for Raw Material Warehouses

- Selective Pallet Racks: Ideal for warehouses needing direct access to each pallet.

- Drive-In/Drive-Through Racks: Perfect for high-density storage, saving more space while accessing fewer SKUs.

- Push-Back Racking: Great for bulk storage, where newer stock is loaded at the front and older items are pushed back.

- Cantilever Racks: Suitable for long or bulky items that cannot fit on conventional pallet racks.

Choosing the Right Pallet Racking System

Factors to consider:

- Material type and weight: Ensures racks can withstand the load.

- Warehouse layout: Proper planning to maximize space and flow.

- Safety standards: Compliance with industry regulations for safe racking solutions.

Key Features of our Raw Material Warehouse Pallet Racking:

- Space Optimization: Effective utilization of warehouse space is crucial for storing raw materials efficiently. Our designed pallet racking systems maximize vertical space, ensuring compact, organized raw material storage. Featuring adjustable shelving levels and customizable configurations, adapts to various sizes, weights, and quantities effortlessly. This helps you make the most of your available space and increase storage capacity.

- Easy Accessibility: Quick and convenient access to raw materials is essential for seamless operations in a warehouse setting. Our pallet racking systems ensure easy accessibility to every raw material item.

- Durability and Strength: Raw materials in industrial environments can vary in size, weight, and form. Our pallet racking systems in the Raw Material Warehouse use robust materials, ensuring durability and strength. These racks safely handle heavy loads in tough industrial settings, offering a reliable, long-lasting storage solution for your raw materials.

- Inventory Management: Effective management of raw material inventory is essential for smooth operations and cost control. Our pallet racking systems ensure precise inventory records. Clear visibility and organization of raw materials aid this. Implement labeling, barcode scanning, and inventory management software for streamlined tracking, stock monitoring, and optimized replenishment.

- Customization and Flexibility: We understand that every warehouse has unique requirements. Our Raw Material Warehouse Pallet Racking systems offer customization options to tailor the racking system to your specific needs. We design and customize systems for your raw material storage needs.

- Safety Measures: We prioritize the safety of your warehouse personnel and your raw materials. Our pallet racking systems prioritize safety with rack guards, load stops, and anti-collapse mechanisms. These ensure accident prevention and protect your inventory. By adhering to industry safety standards and guidelines, we ensure a secure and hazard-free storage environment for your raw materials.

We commit to delivering reliable and efficient pallet rack solutions for raw material warehouses, tailored to your unique operational needs. Benefit from our storage expertise, meticulous attention, and dedication to your satisfaction. Partner with us to optimize raw material storage.